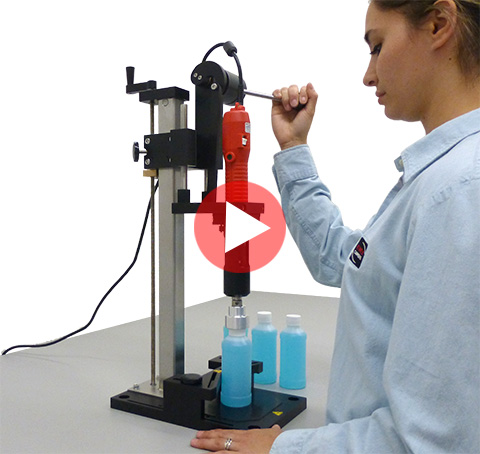

Simple To Operate & Comfortable To Use

We designed the ES™ Table Top Capping Equipment to provide our customers with a compact and easy to use capping machine that is very comfortable to use. The operator simply places the bottle onto the base of the machine and depresses the capping lever; the machine takes care of the rest.

Not only is the ES™ Table Top Capping Equipment an excellent solution for people currently tightening their caps by hand, it even requires less effort to operate than a hand-held capping machine. Below is a listing and explanation of some of the factors that make the ES Table Top Capping Equipment so comfortable to use. In a few of these explanations, we will describe how the ES Table Top Capping Equipment requires less effort to operate than a hand-held capping machine.

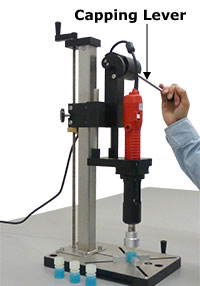

The ES™ Table Top Capping Equipment makes it easy to apply the downward force required during the capping process.

Capping machines use a chuck with inserted soft rubber liner to create grip on a cap. Downward pressure is required during the capping process to push the soft rubber liner into the cap. When the liner is pushed into the cap, it grips the cap which enables the capping motor to tighten the cap onto the bottle. If no downward pressure is applied during the capping process, the liner will simply skid over the cap and the cap will not become tight.

The capping lever on the ES™ Table Top Capping Equipment creates a substantial amount of mechanical advantage that makes it easy to apply the downward force required during the capping process. The operator of a hand-held capping machine must apply the required downward force without any assistance, which requires greater effort.

Chuck With Inserted Liner

The ES™ Table Top Capping Equipment absorbs the torque generated during the capping process so the operator is not exposed to it.

By design, the operator of a hand-held capping machine has to hold the capping machine still during the capping process. As a result, when the machine is applying the required torque to tighten a cap, the operator has to exert an equal amount of torque in the opposite direction to prevent the machine from rotating during the capping process.

The capping motor is mounted on the Table Top Capping Equipment so the operator is never exposed to the twisting torque generated during the capping process.

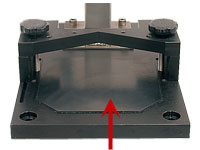

The ES™ Table Top Capping Equipment prevents the bottle from spinning

during the capping process.

The Base of the ES™ Table Top Capping Equipment is covered by an extremely high friction rubber. The downward force generated during the capping process presses the bottom of the bottle firmly into the high friction rubber which works to prevent the bottle from spinning while it is being capped. So much friction is created that the operator usually does not have to hold the bottle while it is being capped. In the event that the base requires some assistance from the operator to completely prevent the bottle from spinning, only the slightest of effort is required

High Friction Rubber Surface

Standard Base