A Kinex Snap Capper Machine applies snap-on caps, push-on caps, and press-on caps onto bottles and containers of all shapes and sizes quickly, quietly and ergonomically. Kinex Snap Cappers eliminate the time consuming and fatiguing process of pushing on caps by hand. Snap capping machines are frequently used in industries like pharmaceutical, chemical, cosmetic, and food and beverage.

Our snap cappers can press plastic caps and metal caps onto glass bottles, metal containers and plastic bottles such as PET, HDPE, LDPE, PVC and PP. Kinex push on bottle capping machines can push on milk caps, sifters, over caps, plastic pull up spout caps into tin cans, and lids onto tin cans.

Kinex push on bottle capping machines are also capable of pressing plugs and fitments into the neck of a container, such as dropper inserts, orifice reducers, dropper tip plugs, as well as the plastic caps, balls and fitments for roll-on containers.

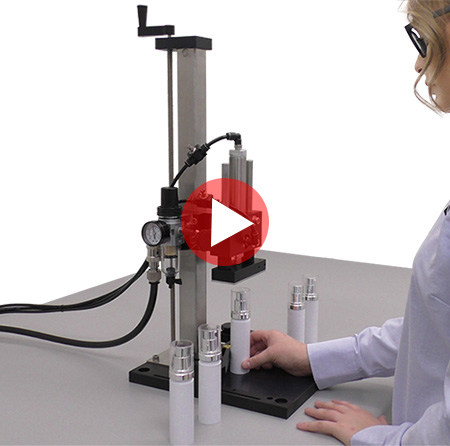

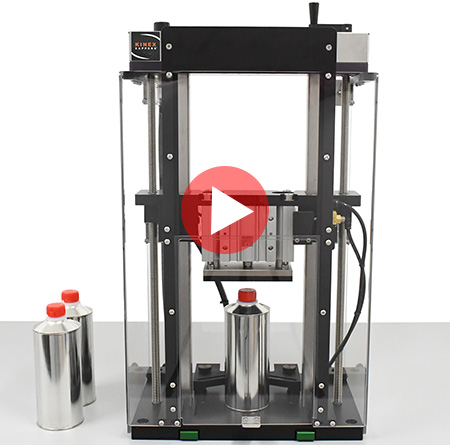

We offer two versions of snap capping machines. Our SD snap capper (standard duty) can press on caps that require between 10 and 80 pounds of force to apply. The Kinex HD snap capper (heavy-duty) can push on caps that require between 75 and 600 pounds of force to apply. The HD Snap Capper is equipped with a polycarbonate safety shield designed to protect the operator from potential bottle breakage. The safety shield features an access door that must be closed for the machine to operate, providing an additional layer of protection.

Key Features

- External Force Adjustment Dial

- Stainless Steel and Anodized Aluminum Construction

- 100% Pneumatic Operation

- Foot Pedal Activated (Dual Push Button is Optional)

- Tool-less Changeover: All adjustments are made by hand

- Continual Height Adjustment

Specifications & Pricing

| Price | $2,450 |

| Pushing / Pressing Force | 10 - 80 lbs. |

| Air Requirements | 10 - 90 PSI @1.0 SCFM |

| Max Bottle Height | 20 inches |

| Max Bottle Diameter | 7.25 inches |

| Weight | 26 lbs. |

| Width | 8 inches |

| Depth | 12 inches |

| Height | 28.5 inches |

Key Features

- External Force Adjustment Dial

- Stainless Steel and Anodized Aluminum Construction

- 100% Pneumatic Operation

- Dual Push Button Operation

- Continual Height Adjustment

- Safety Features:

- Polycarbonate safety shield

- Access door must be closed for the machine to operate

Specifications & Pricing

| Price | $5,750 |

| Pushing / Pressing Force | 75 - 600 lbs. |

| Air Requirements | 20 – 90 PSI @ 2.5 SCFM |

| Max Bottle Height | 12.75 inches |

| Max Bottle Diameter | 8 inches |

| Weight | 50 lbs. |

| Width | 16.5 inches |

| Depth | 10.5 inches |

| Height | 30 inches |