No Matter the Size or Shape of Your Cap

We Have the Perfect Bottle Capping Machine For You.

Kinex Cappers® manufactures capping machines, bottle cappers and cap tighteners that apply screw caps, lug caps and snap-on caps from 10 to 130mm in diameter. We have earned our reputation throughout the industry for manufacturing dependable and long-lasting bottle capping machines that provide excellent repeatable torque accuracy. Our products are designed and built at our New Hampshire, USA factory.

Customer service is our highest priority.

- A person, not a phone system, will answer your call.

- All inquiries are responded to promptly.

- Product pricing and videos can be found on our website.

- We offer a full one-year warranty on all parts and labor.

- We offer a 30-day money back return policy.

- Most orders ship within two business days.

Automatic Capping Machines

Relia-Cap® Automatic

Capping Machine

- Up to 40 Caps per Minute

- Tightens Caps from 10mm - 130mm

- Easy to Install, Set-up & Operate

- Touchscreen Display & Easy to Navigate Menu

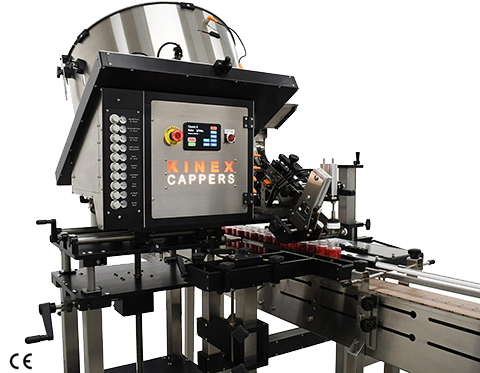

Versa-Max®

Spindle Capper Machine

- Up to 50 Caps per Minute

- Tightens Caps from 15mm - 130mm

- Touchscreen Display & Easy to Navigate Menu

- Applies all styles of screw-on caps including trigger spray caps

Automatic Snap Capper Machine

- Up to 105 Caps per Minute

- External Force Adjustment Dial

- Applies push-on caps, press-on caps, fitments, and snap-on caps

- Touchscreen Display & Easy to Navigate Menu

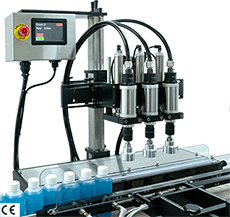

Auto-Max Automatic Screw Capping Machine

- Up to 105 Caps per Minute

- Capping Machinery Tightens Caps from 10mm - 130mm

- Easy to Install, Set-up & Operate

- Choose from 1 to 4 Capping Heads

Cap Feeder

QuickFeed Cap Feeder

The QuickFeed is a complete, ready-to-use cap sorting and cap feeding system. It sorts and feeds caps, places caps on containers, and even starts the caps on the thread, all while managing the flow of bottles entering an exitingthe machine.

- Sorts, feeds & applies up to 60 caps per minute

- Integrated Pick & Place Cap Applicator

- Feeds caps ranging from 18mm -75mm in diameter

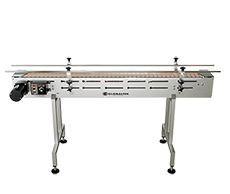

Bottle Conveyors

Bottle Conveyors

- Stainless Steel Inline Bottle Conveyor

- Low Friction Acetal (Delrin) Tabletop Plastic Chain Belt

- Variable Speed Motor & Controller

Rotary Accumulation Tables

Accumulation Tables

- Made in the USA with 100% UL certified materials

- Clockwise and Counterclockwise Rotation

- Adjustable Bottle Guide Rails

- Adjustable Leveling Feet

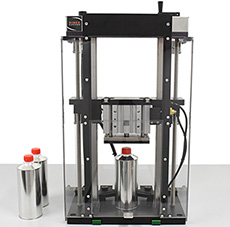

Liquid Filling Machine

Relia-Fill® Liquid Filling Machine

- Filling Accuracy of +/- 0.5%

- Easy to Set Up and Simple to Use

- Clean Up is Quick:

Only the Filling Tube and Nozzle require cleaning

Automatic Filling Machine

Automatic Filling Machines

- Up to 100 Bottles per minute

- Filling Accuracy of +/- 0.5%

- Choose from 1-8 Filling Heads

- Saves & Stores Filling Programs for Future Use

Bottling Lines

Automated Bottling Lines

With reliable Kinex Cappers® bottle packaging machinery, our automated bottling lines provide a cost-effective solution while ensuring exceptional product quality. Customize your line by selecting from our range of bottling equipment to match your unique requirements

- Up to 60 bottles per minute

- Increase production efficiency and throughput

- Enhance product quality and consistency

Benchtop Capping Equipment

SA™ Bench Top

Capping Machine

- Makes Capping Effortless

- Outstanding Torque Accuracy & Repeatability

- Tool-Less Changeover – All Adjustments are Made by Hand.

- Tightens Caps from 10mm - 130mm

PumpCap™

Bottle Capping Machine

- Tightens Them All - Ordinary Caps to Trigger Spray Caps

- Excellent Torque Accuracy & Repeatability

- Capping MachineryTightens Caps from 15mm - 130mm

Snap Capper

Machine

- Applies snap-on caps, push-on caps, and press-on caps

- 100% Pneumatic Operation

- External Force Adjustment Dial

ES™ Table Top

Capping Equipment

- Compact and Easy to Use

- Runs on Standard Electricity with a Direct Plug-in Cord

- Tightens Caps from 10mm - 70mm

Handheld Capping Machines

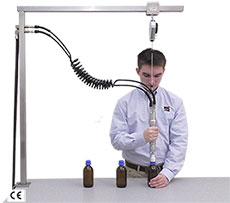

PS™ Pneumatic

Bottle Capper

- Everything You Would Want in a Hand-held Bottle Capper

- Outstanding Repeatable Torque Accuracy from 2 - 200 inch lbs.

- Tightens Caps from 10mm - 130mm

ES™ Bottle

Capping Machine

- Easy to Set Up & Simple to Use

- Excellent Torque Accuracy & Repeatability

- Tightens Caps from 10mm to 70mm

Cap-Rite™

Cap Tighteners

- Outstanding Torque Accuracy of +/- 4%

- Includes a Certificate of Calibration.

- Torque Output is Set and Locked to Your Specification.

ST™

Cap Tightener

- Constructed of 316 stainless steel

- Ideal for use in Clean, Sterile or Harsh Environments

- Tightens Caps from 15mm - 130mm

- Accuracy: +/- 0.5% of full scale

- Easy to use

- Can run on battery power

Bottle Capping Chucks

Deep Well Chucks

- For caps with external features such as dropper, mist spray, yorker & push-pull caps

Blog

Managing the Effects of Momentum on Capping Torque

When capping a bottle, your ultimate goal is to apply the perfect amount of torque. The perfect amount of torque properly seals the contents within your container making sure no leaking occurs. However, there are variables that can affect torque. One of these variables is momentum. Continue reading