A bottling line is a collection of interconnected machines and equipment, systematically arranged, that perform the many different processes required to fill a bottle, and to prepare the bottle and its contents for commercial sale, from start to finish. A few of the most common types of machines included on bottling lines are filling machines, cap feeders, capping machines, labeling machines, bottle conveyors and accumulation tables.

At Kinex Cappers®, we take pride in manufacturing top-quality bottling line equipment right here in the USA. With a focus on reliability and durability, our machines are built to ensure a smooth bottling process, minimize downtime, and deliver consistent performance.

We understand that every business has unique bottling needs. That's why we offer a range of bottling equipment that can be purchased individually, allowing you to build a customized filling and capping line that precisely fits your requirements.

This modular approach provides you with the flexibility to start with the equipment you need today and then easily expand or upgrade your bottle packaging line as your business grows. With our cost-effective solutions, you won't have to compromise your budget while enjoying exceptional value.

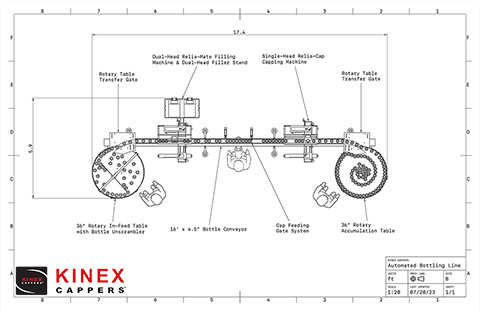

Automated Bottling Line

Our automated bottling lines provide an economical option to meet your production requirements. Operating at impressive speeds of up to 40 bottles per minute, these systems provide efficient performance. They incorporate reliable and accurate Kinex Cappers® bottling equipment to ensure excellent product quality.

Bottles per minute: Up to 40

Staff needed: 2-3

Price Range: $40,835 - $81,915

Price of line shown in video: $54,135

You can build your own automated bottling line from any of our available bottling equipment. The equipment shown in the video to the right is listed and linked to below:

- 2 Head Relia-Mate™ Filling Machine.

- Relia-Cap® Capping Machine.

- 16 foot, 4.5 inch wide, inline conveyor.

- 3 foot rotary accumulation table with unscrambler.

- 3 foot rotary accumulation table.

- Cap Feeding Gate System.

- Table to conveyor adjustable gate transfer system. Quantity 2.

Automatic Bottling Line

Our fully automatic bottling lines feature the Kinex QuickFeed™ cap feeder, which completely automates the cap sorting, feeding, and placing operations. By eliminating the need for manual intervention in these tasks, substantial cost savings are realized, and the production capacity is increased to a rate of up to 60 bottles per minute.

Bottles per minute: Up to 60

Staff needed: 1-2

Price Range: $73,585 - $115,015

Price of line shown in video: $101,850

You can build your own fully automatic bottling line from any of our available bottling equipment. The equipment shown in the video to the right is listed and linked to below:

- 4 Head Relia-Max™ Filling Machine.

- QuickFeed™ Cap Feeder.

- Auto-Max™ Single Head Capping Machine.

- 20 foot, 4.5 inch wide, inline conveyor.

- 3 foot rotary accumulation table with unscrambler.

- 3 foot rotary accumulation table.

- Table to conveyor adjustable gate transfer system. Quantity 2.

We've had a fantastic experience working with Kinex for our bottling line. Their team, especially Stephanie on the sales side and Colin for technical support, has been incredibly helpful and thorough throughout the entire process. Both are prompt in addressing any questions or concerns we have, ensuring that our operations run smoothly as we scale. Their commitment to excellent service has made a significant positive impact on our business.

Jimmy Semrick, Brella Drops

Chicago, Illinois, USA

Things to consider before purchasing a bottling line.

- Production Requirements: Determine your desired production rate to find a bottle packaging line that meets or exceeds your needs.

- Budget and Scalability: Evaluate upfront cost, productivity gains, and future expansion potential.

- Space and Layout: Verify that the bottling line you plan to purchase fits your production facility. Examine your facility for access points to electricity and compressed air, as well as any relevant structural features such as ceiling height, columns, or swinging doors. Carefully review the layout drawing provided to ensure a successful installation.

- Personnel Considerations: It is essential to have capable personnel with mechanical aptitude and a willingness to learn who can operate and troubleshoot your bottling line equipment. If your staff is not well-suited for automation, consider a semi-automatic or manual bottling line.

- Adaptability: Invest in modular equipment that can adapt to product changes and scale with your company.

- Availability of Replacement Parts: This may come as a surprise, but it is quite common to face difficulties in obtaining replacement parts for bottle packaging machines, even if they are relatively new. This is particularly problematic for machines that are manufactured overseas. You will never have this problem when purchasing packaging machinery from Kinex Cappers®. We are dedicated to long-term customer support and replacement parts for your machine will always be available.

- Technical Support: Technical support and repair services may occasionally be needed for capping and filling lines. We provide free, unlimited lifetime technical support for your bottle packaging line.

- Supplier Reputation and References: When investing in a bottling line, it's crucial to recognize that you are establishing a long-term relationship with the manufacturer. You should seek a supplier with an excellent reputation for product quality and reliability. Our machines are known for their ease of use, rugged design, and unmatched reliability, as evidenced by the testimonials on our website.

Create your Bottling Line from the Equipment shown below

How To Order a Bottle Packaging Line

If you are interested in purchasing a bottling line, please send samples of your caps, containers, and in some cases your product. This will allow us to test the bottling equipment of your choice with your specific product to ensure that you will be very pleased with your purchase. We will also send you videos of the bottling equipment processing your containers so you can visualize how your new bottle packaging line will operate. In addition, we will record, save, and share with you all of the recommended settings for each piece of equipment so you can get up and running quickly.

When sending samples, please include the following:

- Your complete contact information.

- Please indicate the types of bottling equipment you would like to include on your bottle filling line.

- 15 empty containers for up to five unique applications.

- 50 corresponding caps for each unique application.

- (Conditional) If you are interested in a bottle filling line and you have a highly viscous, or otherwise challenging product, we may have you send an amount of your product that would be sufficient for testing with the filling machines. If this applies to any of your applications, please call before sending your samples so we can discuss.

- (Conditional) If you are interested in a cap feeder, please send 250 caps and 25 bottles for each unique application to allow for thorough testing

Please send the samples to the following address:

Kinex Cappers

Attn: Sales Department

6 Columbia Drive, Unit B

Amherst, NH 03031

USA