Options & Accessories

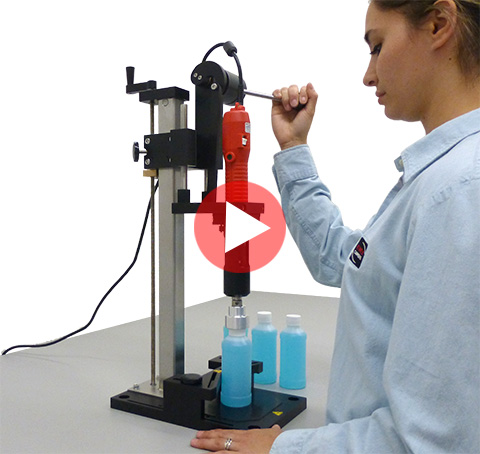

Lever Activated Bottle Gripping Base

The Lever Activated Base perfectly centers the bottle in preparation for capping and holds the bottle to prevent it from spinning during the capping process. The four continuously adjustable grippers can be set to center and hold any bottle regardless of its shape. It is an optional replacement for the standard base used with the SA™, ES Table Top™, and PumpCap™ Capping Machines.

The Lever Activated Base is particularly well suited for use with very short or narrow bottles. Very short containers are difficult to hold during the capping process. There is very little space for the operator’s hand to hold the container without being very close to the cap when the machine is tightening it. The Lever Activated Base holds the bottle firmly and allows the operator to remove their hands from the capping area while the cap is being tightened.

The Lever Activated Base works with bottles up to 6.5 inches in diameter. It is constructed of 304 stainless steel and hard coat anodized aluminum for outstanding corrosion resistance.

The Lever Activated Base is an optional upgrade to the standard base offered with the ES Tabletop capping machine. The cost of the upgrade is $750. You can select it when you place your order. Or you can purchase it separately at the link below.

Price if purchased separately: $1,150 Buy Now

Adjustable Sliding Arms - Square/Rectangular Bottle Holders

Adjustable Sliding Arms can be added to the Backstop of the standard base to allow for easy centering of a square or rectangular bottle under the capping motor in preparation for capping.

The arms are attached to the two grooves that run parallel to the V-shape of the Backstop. The arms can be positioned anywhere along these grooves to accommodate any square or rectangular bottle up to 8.5 inches in width. The arms are available in 2, 3, 4 and 5 inch lengths.

To complete purchase please continue to the ES Tabletop Pricing Page or or contact us.

Adjustable

Sliding Arms

Come In Five Sizes

Machined Chucks

Machined chucks are custom made to fit the rib pattern of a particular cap. They fit the cap in the same way as a socket fits a nut. Machined chucks provide extreme gripping power that make them very useful for certain types of challenging jobs, a few of which are described below

- De-Capping

The vast majority of de-capping jobs require a machined chuck. In most cases a standard chuck with inserted liner cannot provide enough gripping power to remove a tight cap. Generally what occurs is that the liner simply skids over the cap without removing it.

Machined chucks grip a cap so perfectly that it makes the removal of even the tightest of caps very easy. - Clean Room & Sterile Environments

The urethane or white rubber inserts within a standard chuck will wear slowly over time and can occasionally leave very small amounts of urethane or white rubber particles on the caps they tighten. These particles may not be allowed in certain clean, sterile or controlled environments.

Machined chucks are ideal for clean environments since they do not wear and do not create particles.

Machined chucks also improve torque accuracy and never have to be replaced. - Extreme Torque Applications

When a cap has to be applied with an unusual or extreme level of tightness, a machined chuck is the perfect solution. A machined chuck can always apply as much torque as is necessary and will do so quite easily. Machined chucks also improve torque accuracy and never have to be replaced.

Machined chucks cannot be purchased through our shopping cart. Please contact us to order.

Machined Chucks

Standard Chuck

with Urethane Liner