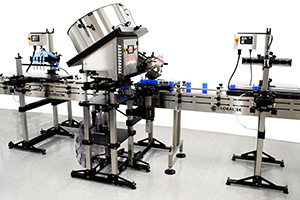

The Versa-Max® spindle capper machine tightens all types of screw-on caps, from standard caps to trigger spray caps, at speeds of up to 50 caps per minute. We designed the Versa-Max® spindle capping machine to provide our customers with an inline capping machine that is easy to setup, easy to adjust, and easy to use.

Before the Versa-Max®, spindle cappers had a well-deserved reputation for being difficult to use. They required a lot of tinkering and tweaking by experienced service technicians in order to achieve a tight cap. The Versa-Max® spindle capping machine has put an end to this frustration. The Versa-Max® provides outstanding grip on the cap and as a result, setup is fast and easy, and you can tighten your cap with as much torque as you would like with outstanding torque repeatability.

Testimonial

The Versa-Max® Capping Machine is easy to use, saved us a lot of time, and is a great improvement to our business! The Versa-Max®, like other Kinex capping machines we own, is reliable and tightens each of our many different cap sizes perfectly. Keep up the great work.

Oded Lotan, Anna Lotan Ltd

Or Akiva, Israel

Other Products You Might Like:

The Versa-Max® inline spindle capper machine features a touchscreen display and easy to navigate menu. It displays real time production information, including the number of caps it has tightened and the production rate in bottles per minute. All program adjustments are at your fingertips to provide you with complete control over the capping machine. Capping programs can be saved and stored for future use.

The Versa-Max® Inline Capping Machine offers unbeatable versatility. It tightens caps from 15mm – 130mm in diameter onto bottles ranging from 0.75 to 12 inches wide. It applies all styles of plastic and metal threaded caps. Due to their extreme flexibility, spindle capper machines are used in the cosmetic industry, food and beverage industry, chemical industry, pharmaceutical industry and many others.

Inline Capper Machine

Key Features

- Up to 50 Bottles Per Minute

- Stainless Steel and Anodized Aluminum Construction

- Easy to Set-up. Easy to Adjust

- Touchscreen Display & Navigation

- Easy to Navigate Menu

- Calculates and Displays the Production Rate (Bottles/Minute)

- Counts and Displays the Number of Bottles Capped

- Saves and Stores Capping Programs for Future Use

- External Torque Adjustment Dial

- Excellent Repeatable Torque Accuracy

- The Versa-Max® spindle capper machine is CE marked (CE Certified)

Specifications & Pricing

| Price | $20,950 |

| Minimum Cap Size | 15mm |

| Maximum Cap Size | 130mm |

| Torque Range | 0-100 inch pounds |

| Min Bottle Width | 0.75 inches |

| Max Bottle Width | 12 inches |

| Min Bottle Height | 2.25 inches* |

| Max Bottle Height | 17 inches |

| Height | 64.2 inches |

| Width | 30 inches |

| Depth | 39.6 inches |

| Weight | 170 lbs. |

| Air Requirements | 90-125 PSI @ 12 SCFM |

| Electrical Requirements | 100-240VAC, 50/60HZ. Single Phase |

* Pucks can be utilized to allow the machine to accept containers less than 2.25 inches in height.

How To Order

If you are interested in purchasing a Versa-Max® automatic inline capping machine, we will require samples of your caps and containers. This will allow us to test the Versa-Max® with your caps and containers to ensure that you will be very pleased with your purchase. If you would like, we will be happy to send you videos of the Versa-Max® tightening your caps onto your containers. In addition, we will record, save, and share with you all of the recommended settings so you can get up and running quickly.

When sending samples, please include the following:

- Your complete contact information.

- 8 empty containers for up to five unique applications.

- 25-30 corresponding caps for each unique application.

Please send the samples to the following address:

Kinex Cappers

Attn: Sales Department

6 Columbia Drive, Unit B

Amherst, NH 03031

USA

Bottling Line

Bottling Line