Options & Accessories

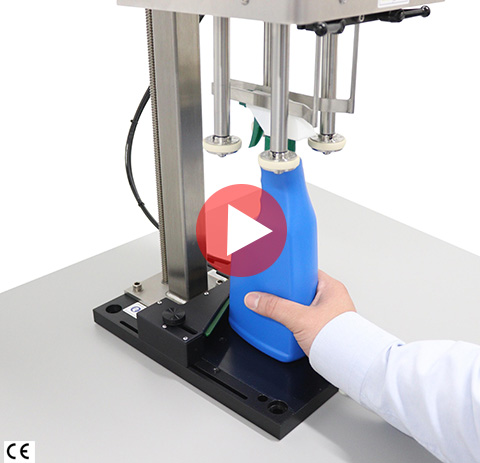

Bottle Activated Backstop

The Bottle Activated Backstop includes a built-in switch that initiates the capping process when the bottle is pressed against it. It eliminates the need to depress a foot pedal or dual push buttons and as a result increases the speed and productivity of the capping process.

The Bottle Activated Backstop accommodates bottles up to 6.50 inches in diameter and is constructed of 304 stainless steel and hard coat anodized aluminum for outstanding corrosion resistance.

The Bottle Activated Backstop is an optional upgrade. The cost of the upgrade is $725. You can purchase this upgrade when you place your order.

Dual Push Button Activated Bottle Gripping Base

The Dual Push Button Activated Base perfectly centers the bottle in preparation for capping and holds the bottle to prevent it from spinning during the capping process. The four continuously adjustable grippers can be set to center and hold any bottle regardless of its shape. It is an optional replacement for the standard base used with the SA™ and PumpCap™ Capping Machines.

Dual push buttons are considered safeguarding devices. The two push buttons must be depressed simultaneously to initiate the capping process, ensuring that the operator’s hands are removed from the capping area during the capping process. The Dual Push Button Base accommodates bottles up to 6.33 inches in diameter. Constructed of 304 stainless steel and hard coat anodized aluminum for outstanding corrosion resistance.

The Dual Push Button Activated Base is an optional upgrade. The cost of the upgrade is $1,425. You can purchase this upgrade when you place your order.

Foot Pedal Activated Bottle Gripping Base

The Foot Pedal Activated Base perfectly centers the bottle in preparation for capping and holds the bottle to prevent it from spinning during the capping process. The four continuously adjustable grippers can be set to center and hold any bottle regardless of its shape. It is an optional replacement for the standard base used with the SA™ and PumpCap™ Capping Machines.

The foot pedal Activated Base allows for complete hands free operation of the capping machine which increases the speed and productivity of the capping process. It accommodates bottles up to 6.33 inches in diameter and is constructed of 304 stainless steel and hard coat anodized aluminum for outstanding corrosion resistance.

The Foot Pedal Activated Bottle Griping Base is an optional upgrade. The cost of the upgrade is $1,425. You can purchase this upgrade when you place your order.

Universal Base

The Universal Base combines a Dual Push Button Base and a Foot Pedal Activated Base within a single machine. With the simple flip of a switch, transition from dual push button activation to foot pedal activation, depending on operator preference.

The Universal Base accommodates bottles up to 6.33 inches in diameter and is constructed of 304 stainless steel and hard coat anodized aluminum for outstanding corrosion resistance

To complete purchase please continue to the PumpCap™ Pricing Page.

Adjustable Sliding Arms - Square/Rectangular Bottle Holders

Adjustable Sliding Arms can be added to the Backstop of the standard base to allow for easy centering of a square or rectangular bottle under the capping motor in preparation for capping.

The arms are attached to the two grooves that run parallel to the V-shape of the Back stop. The arms can be positioned anywhere along these grooves to accommodate any square or rectangular bottle up to 8.5 inches in width. The arms are available in 2, 3, 4 and 5 inch lengths.

To complete purchase please continue to the PumpCap Pricing Page or or contact us.

Adjustable Sliding Arms

Come in Five Sizes

Oil Free Pneumatic Motors for Clean Environments

Fit your PumpCap™ Capping Machinse with an optional Oil Free Pneumatic Motor. Just as the name suggests, our Oil-Free Pneumatic Motors do not require lubrication.

Standard pneumatic motors cannot be used in many clean environments because they expel a tiny amount of lubrication in the exhaust. Although the amount of oil they expel is so minimal that it is completely imperceptible, it is still not suitable for a clean room environment. Since our oil free motors require no lubrication, the exhaust air exiting the machine is as clean as the compressed air going into it.

The oil free pneumatic motor is an optional upgrade to the standard motor offered with the PumpCap Spindle Capper. The cost of the upgrade is $250 You can purchase this upgrade when you place your order.